Revolutionizing Connectivity: Amphenol's Next-Generation Hardline Connectors

Solve Deployment & Maintenance Challenges for Today's Networks

Contact UsAmphenol’s new hardline connectors address the key deployment and ongoing maintenance challenges of today’s most commonly used connectors.

Despite a desire to move to all-fiber networks, practicality forces service providers to continue to invest heavily in hardline copper infrastructure. While some vendors are satisfied to continue to supply the same ”bread & butter” hardline products that have contributed to their bottom line for years, Amphenol continues to innovate.

Benefits:

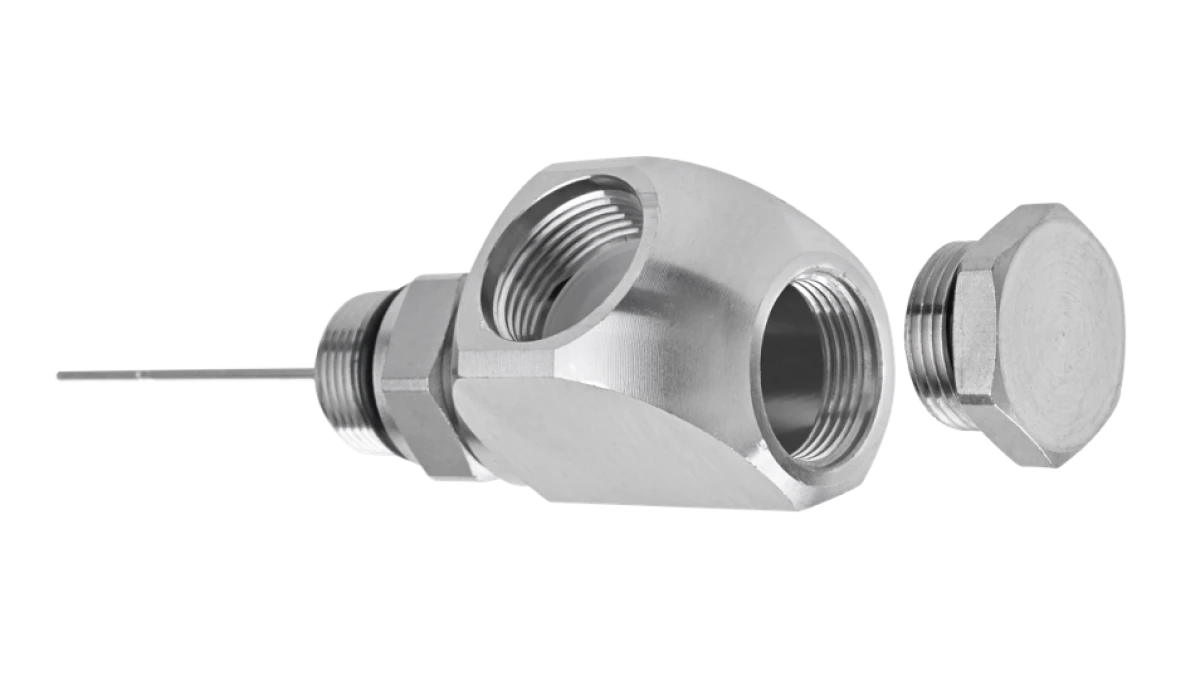

- Easy installation, especially in tight or difficult installation site

- Prevents cable from turning during installation

- Applies uniform grip and correct pressure to the cable center conductor when tightening connector it reduces risk of intermodulation distortion (IMD)

- Extremely resistant to chemical, salt, oils and pollutants

- Minimizes noise in any environment

- Especially useful in tight or difficult installation sites, no need for torque wrench

Features:

- Reduced tightening torque

- Cable anti-rotation locked

- High-Tec polymer activator system & multigrip seizing mechanism

- Multislot ferrule

- Brass - Utilizes unique Nitin-6™ plating

- High-tech polymer insulator

- Full mechanical stop on body & main body

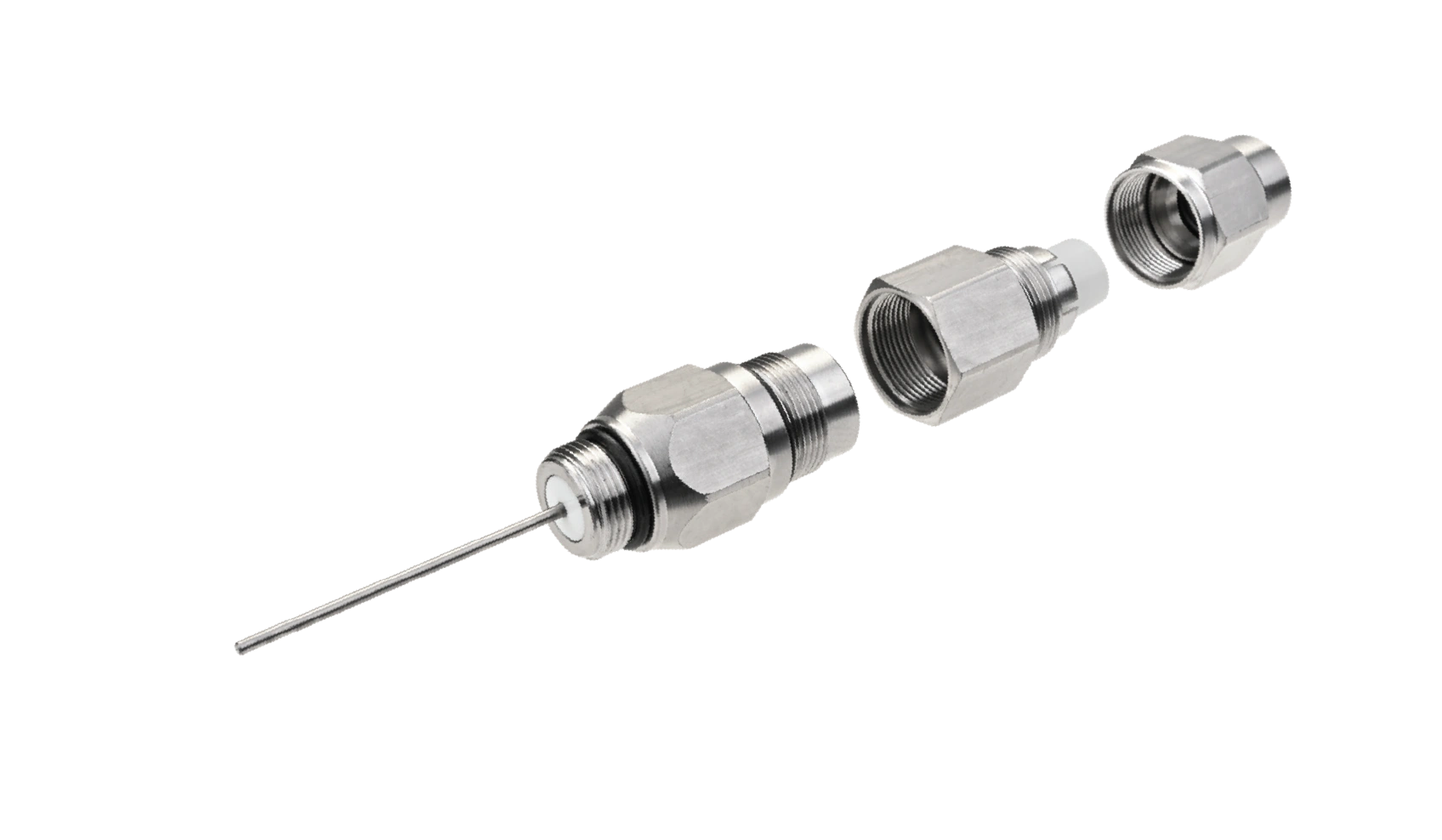

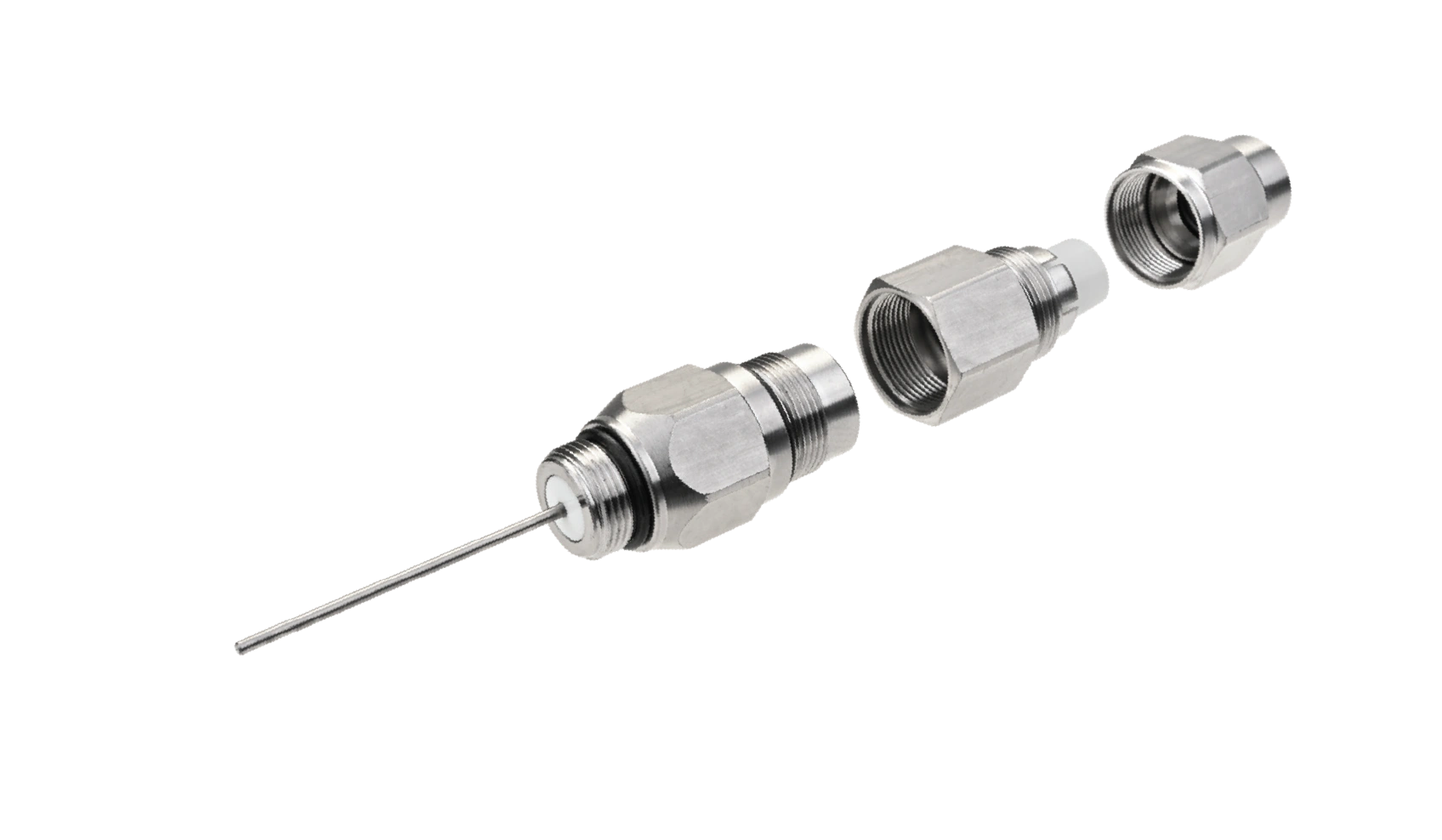

- Three piece design

- Robust brass construction

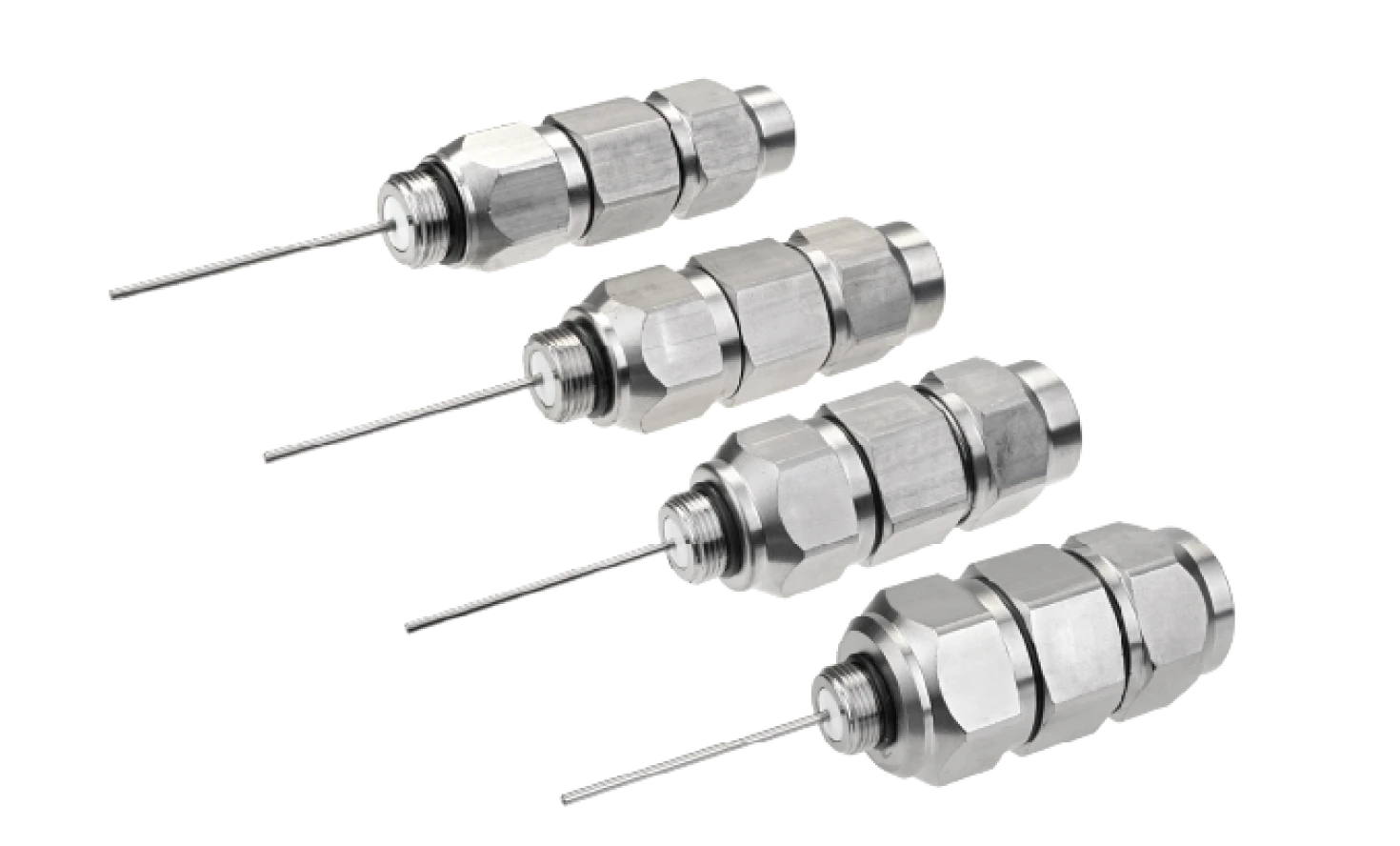

- One piece 3” & 6” extension pin

- Smooth thread design

- Universal center conductor length

- Designed to be re-usable

Why Brass?

Brass does not experience Galling - An adhesive wear on sliding metallic surfaces (Sometimes referred to as “Cold Weld”)

Unlike softer aluminum, brass provides operational threads even after over-torquing or side-loading

Less likely to damage internal threads of housing during side-loading

Clean disassembly without introduction of metal into cable

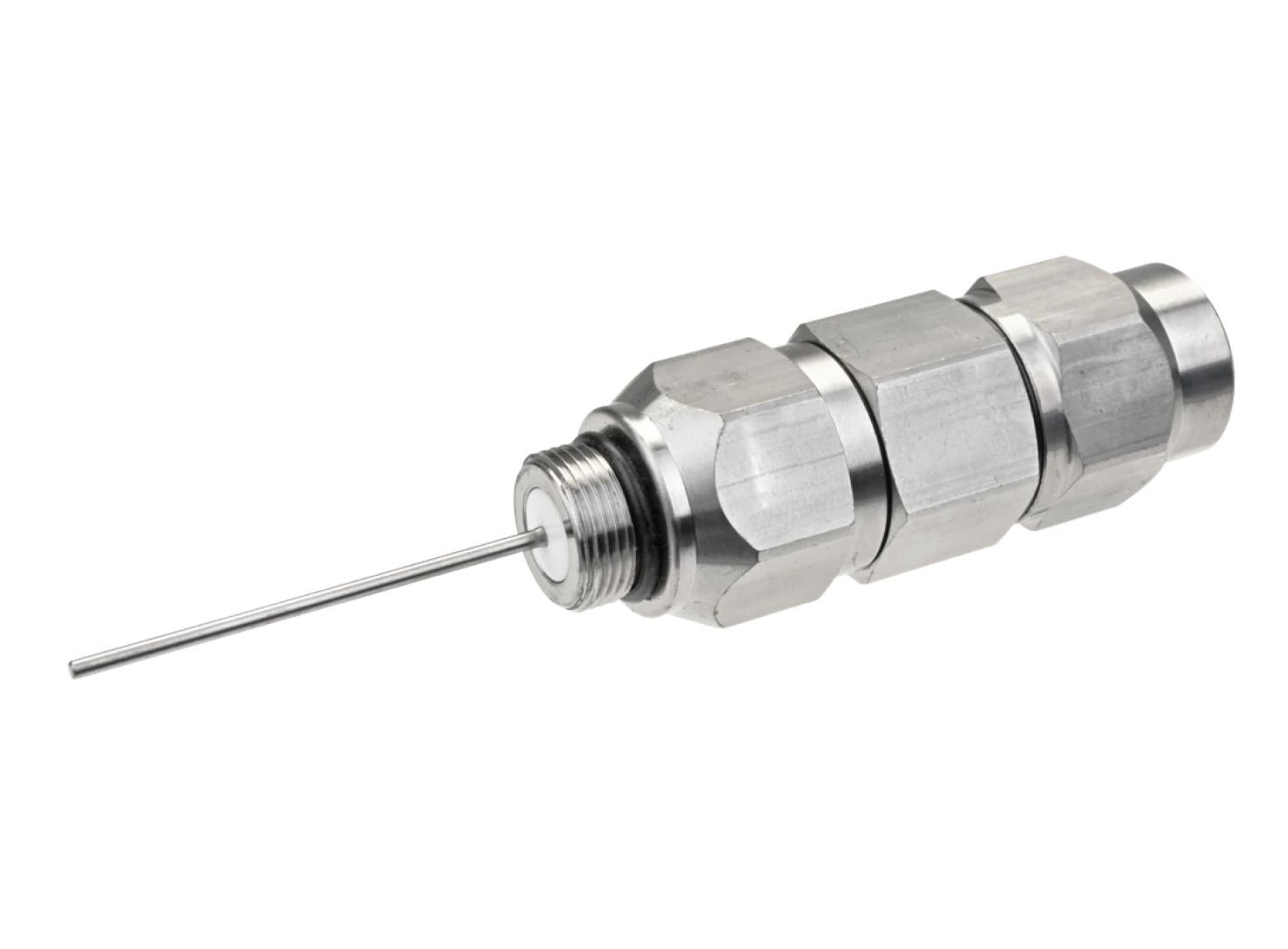

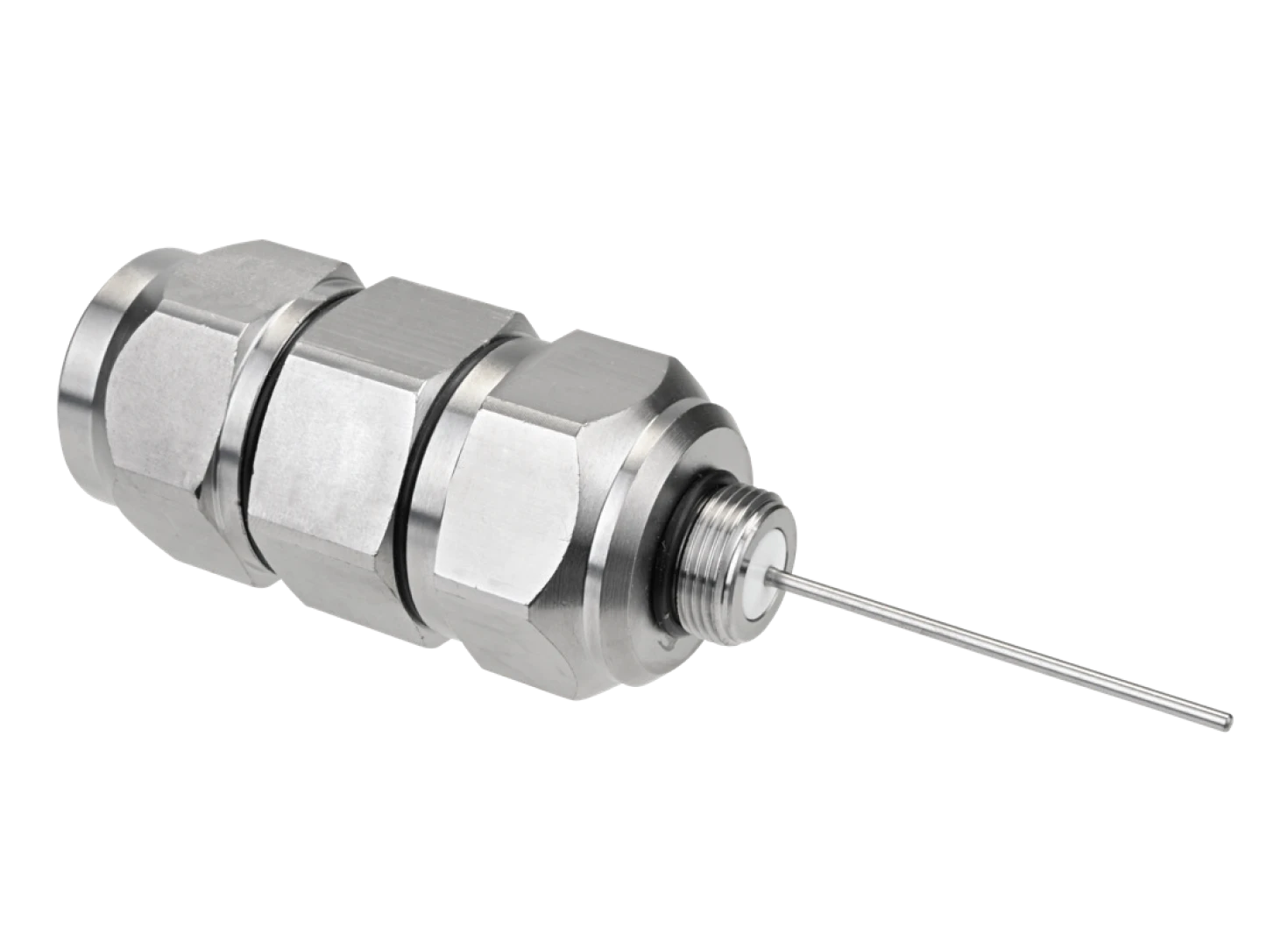

Pin Connectors – Enhanced Seizing Design:

- Compact and slim

- Easy transitions for Heat Shrink

- Enhanced non-destructive seizing doesn’t break through cladding for superior performance at higher frequencies

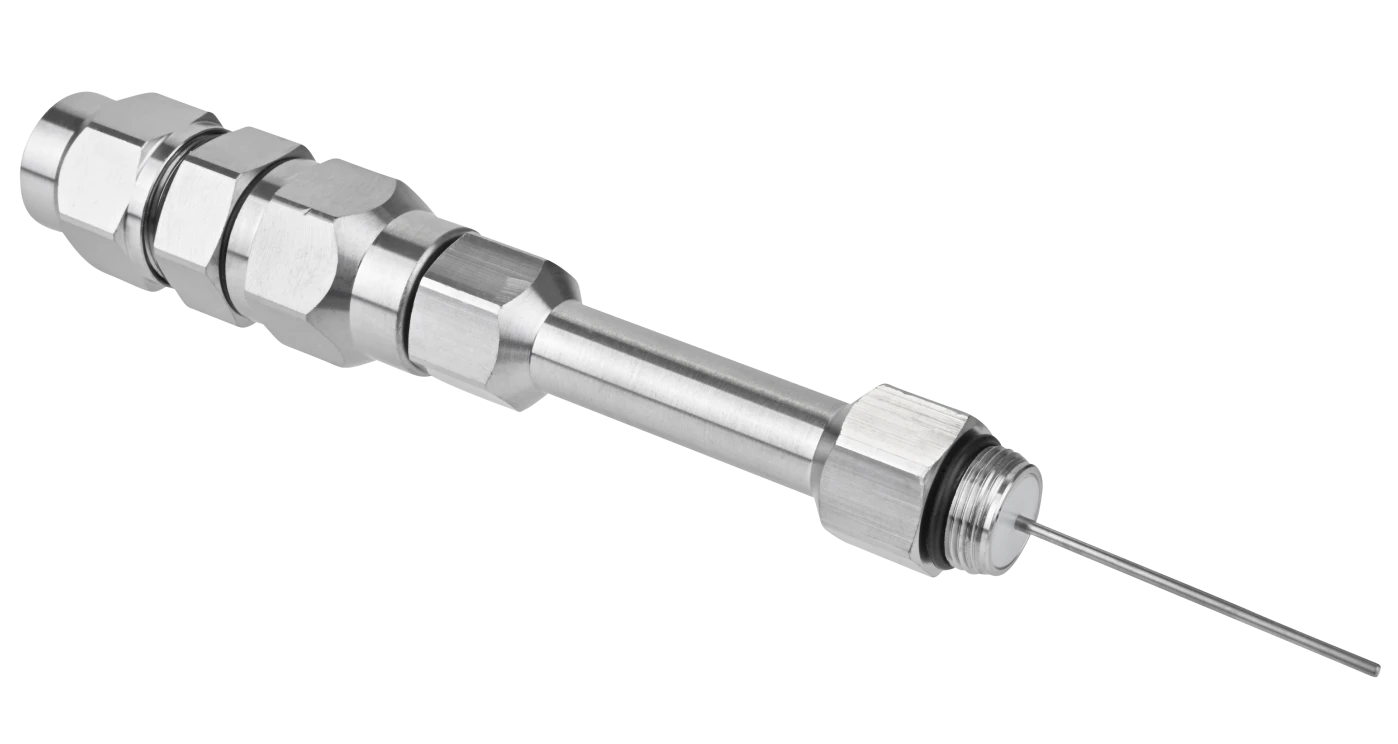

Extensions

- 3” and 6” Extensions have a full-length center pin

- Eliminates reflections within the extension and properly passes AC

- Multiple wrench flats along extension for hard-to-reach areas

- Common Middle Nut/Backnut/ and cable prep with

- Pin Connectors